Optimal Timing for Shut Off Valve Replacement

Understanding the optimal timing for shut off valve replacements can help prevent water damage, reduce repair costs, and ensure proper system operation. Proper scheduling depends on factors such as valve age, usage, and signs of wear. Regular inspections can identify issues early, minimizing disruptions and costly repairs.

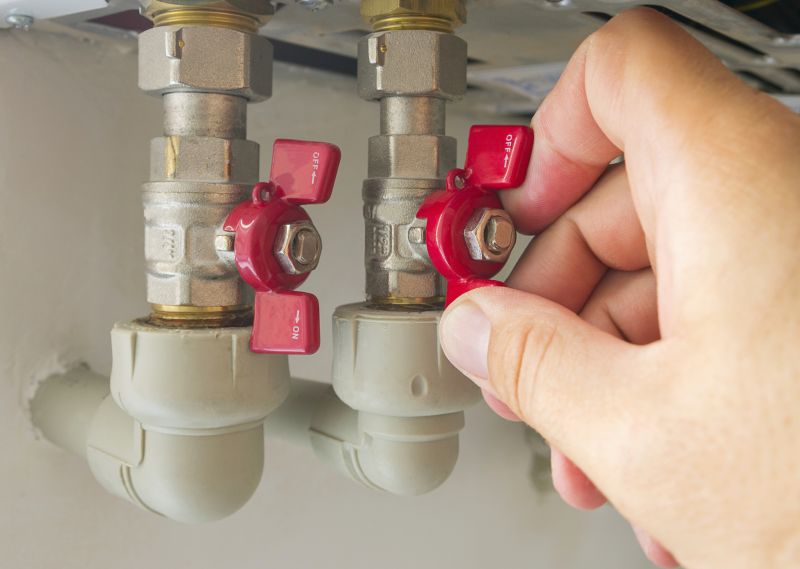

Leaking, difficulty turning, or rust are indicators that a shut off valve may need replacement.

Replacing valves during scheduled maintenance or when plumbing is already accessible reduces costs and inconvenience.

Preventing leaks and water damage, improving system efficiency, and avoiding emergency repairs are key advantages.

Valves typically last 10-15 years; replacements are recommended as they near this age or show signs of deterioration.

Routine inspections help identify early signs of failure.

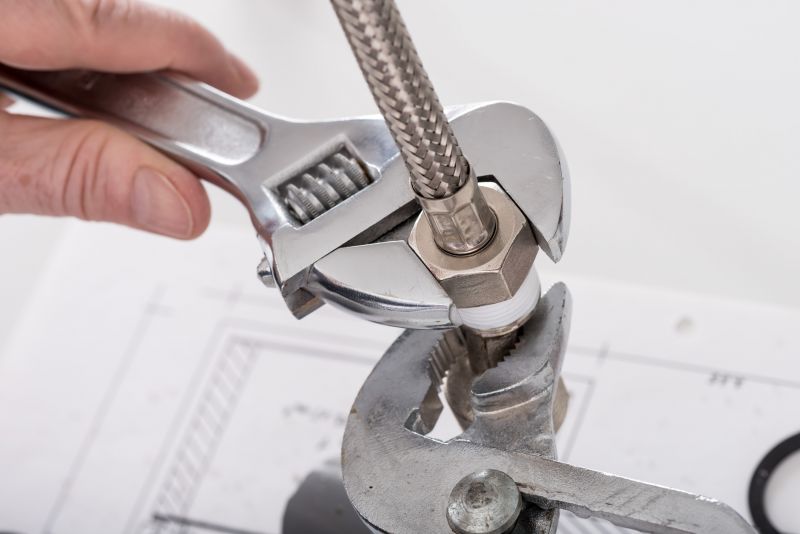

Proper techniques ensure reliable operation and prevent leaks.

Essential tools include wrenches, replacement valves, and sealing materials.

Ways to make Shut Off Valve Replacements work in tight or awkward layouts.

Popular materials for Shut Off Valve Replacements and why they hold up over time.

Simple add-ons that improve Shut Off Valve Replacements without blowing the budget.

Regular maintenance extends valve lifespan.

Corrosion indicates the need for replacement to prevent leaks.

Proper installation ensures system integrity and ease of future replacements.

Quick response minimizes water damage during failures.

High-end options that actually feel worth it for Shut Off Valve Replacements.

Finishes and colors that play nicely with Shut Off Valve Replacements.

Little measurements that prevent headaches on Shut Off Valve Replacements day.

A 60-second routine that keeps Shut Off Valve Replacements looking new.

| Factor | Recommendation |

|---|---|

| Age of Valve | Replace after 10-15 years or if signs of wear appear |

| Signs of Leakage | Replace immediately to prevent water damage |

| Usage Frequency | High-use areas may need more frequent replacements |

| Seasonal Timing | Spring or fall are ideal for scheduled replacements |

| System Upgrades | Replace valves during major plumbing upgrades |

Specialized tools facilitate efficient replacements.

Visual inspection helps detect early corrosion damage.

Ensuring tight seals prevents leaks.

Testing confirms proper valve operation.

A frequent mistake in Shut Off Valve Replacements and how to dodge it.

Small tweaks to make Shut Off Valve Replacements safer and easier to use.

Lower-waste or water-saving choices for Shut Off Valve Replacements.

The short, realistic tool list for quality Shut Off Valve Replacements.

Timely replacement of shut off valves is essential for maintaining plumbing system integrity and avoiding costly water damage. Regular inspections and awareness of signs indicating wear can help determine the best time for replacement. Planning replacements during scheduled maintenance or off-peak seasons minimizes inconvenience and expense. Proper installation and use of quality materials ensure durability and reliable operation.

High-quality components improve longevity.

Wrenches and sealing materials are essential.

Routine checks help identify issues early.

Properly installed valves ensure system integrity.

Rough timing from prep to clean-up for Shut Off Valve Replacements.

Quick checks and paperwork to keep after Shut Off Valve Replacements.

Examples that show the impact a good Shut Off Valve Replacements can make.

Ways to make Shut Off Valve Replacements work in tight or awkward layouts.

If interested in scheduling a shut off valve replacement, filling out the contact form provides a convenient way to initiate the process. Early planning can help avoid emergencies and ensure plumbing systems operate smoothly.